Cut Shipping Costs With Dimensional Weight Calculations

In shipping, every cubic inch counts. And if you’re not accounting for dimensional weight, you’re probably spending more than you should to move air.

Dimensional weight (DIM weight) is how carriers price shipments based not just on how heavy a package is, but how much space it takes up. If you’ve ever shipped a bulky item that barely moved the scale, only to be charged like it weighed a hundred pounds, you’ve seen DIM weight in action. It’s especially costly for businesses shipping high volumes of lightweight or irregular-sized goods.

If you pack a box full of helium filled balloons, the box would weigh next to nothing. But in shipping, space is money. You have to pay for the space it takes up on a pallet or in a truck. If you’re not calculating dimensional weight correctly (and early), you’re essentially paying to ship air.

Let’s break it down.

What is dimensional weight?

Dimensional weight is a pricing method used by shipping carriers to reflect the amount of space a package occupies in relation to its actual w

eight. Instead of charging solely by the number on the scale, carriers charge based on whichever is greater: the actual weight or the dimensional weight.

This matters most when you’re shipping large, lightweight items like pillows, plastic containers, or, yes, a box of packing peanuts. A package might weigh only five pounds, but if it takes up the same space as a 20-pound box, the carrier will likely bill you for 20 pounds.

In short:

- Actual weight is what the package physically weighs.

- Dimensional weight is what the package is priced as based on its size.

How to calculate dimensional weight

Don’t get caught off guard by your shipping charges! You can calculate DIM weight as follows:

1. Measure your package

The length, width, and height of the package is used in calculating the dimensional weight. Sadly, you can’t rely on the dimensions printed on the box because they may not be accurate once the box is packed.

2. Round each measurement

Carriers require that you round each dimension to the nearest whole inch. So for example, if the measurement is 10.5 inches, you would round up to 11 inches. If it’s less than 10.5 inches, you can round down to 10. Always round each dimension separately.

3. Calculate volume

To find the volume, multiply the rounded length x width x height. This will give you the cubic volume in inches. A box measuring 30 x 12 x 12 would be 4,320 cubic inches.

4. Divide by the DIM factor

Now, divide the volume by the carrier’s DIM divisor. The default for most domestic shipments (UPS, FedEx, USPS) is 166. For international shipments, the carrier default is 139.

Using the example above, 4,320 divided by 166 is 26 pounds for a domestic shipment.

5. Compare to actual weight

Next weight the package on a scale. Whichever number is higher—the actual or dimensional weight—is the number you’ll be billed for.

With our example above, if the actual weight is 12 pounds, you’ll get charged for a DIM weight of 26 pounds. If the actual weight is 30 pounds, you’ll get charged for 30 pounds.

Account for dimensional weight with Cube-IQ

Most shippers slip up here: they calculate dimensional weight after packing the box. Why is this a problem? When the freight is ready to go, and the carrier is selected, the cost is locked in. Just like that, they’ve missed out on cost-saving opportunities.

You wouldn’t wait to figure out how much legroom you need until after boarding the plane, would you? If you need more legroom, you buy a seat with more space for your long legs. Once you’re on the plane it’s too hard to adjust.

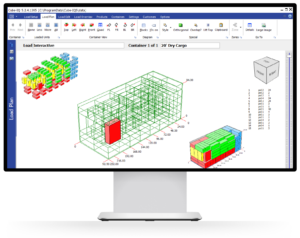

Cube-IQ takes a smarter approach. It calculates dimensional weight during load planning, so your team can optimize before a single box is packed. Whether you’re working with small parcels or large pallets, Cube-IQ helps you choose the best configuration, factoring in dimensional weight in real time.

Let’s go back to that 12 pound package. You don’t want to pay for 26 pounds if you can help it. If the product can fit into a 12 x 12 x 12 box, the dimensional weight for that would be 10 pounds. You would be charged to ship 12 pounds—the actual weight.

Need to work in inches and pounds one day and centimeters and kilos the next? Cube-IQ supports mixed units, meaning it is ideal for global shipping teams that need flexibility and precision.

Best of all, Cube-IQ simulates multiple packing options so you can compare outcomes and choose the most cost-effective strategy before anyone picks up a tape gun.

Common mistakes and how to avoid them

1. Incorrect box size

Why it’s a problem: Oversized boxes are DIM weight traps. You might think you’re protecting the product, but you’re really just inflating shipping costs.

How to avoid it: Use right-sized boxes that fit your product snugly. Reduce unnecessary void space and consider custom packaging if your inventory has consistent dimensions.

2. Neglecting packaging weight

Why it’s a problem: Packing materials like bubble wrap, tape, and foam add weight that is often overlooked. That leads to unexpected costs and underbilled shipments.

How to avoid it: Weigh the fully packed box, not just the product. In addition, keep track of packaging weight separately to improve your shipping estimates and margin forecasts.

3. Inaccurate measurements

Why it’s a problem: Measurement errors, especially rounding down, can lead to billing disputes or surprise fees when the carrier re-measures.

How to avoid it: Always measure from the longest points. Round up, use consistent measuring tools, and consider automating measurements with scanning systems if they are available to you.

4. Dimensional weight vs. actual weight

Why it’s a problem: If your shipping team is focusing only on actual weight, it could be a problem. In many cases, DIM weight is higher, and the carrier will choose the higher option.

How to avoid it: Calculate both and bill your customers (or build pricing models) accordingly. Tools like Cube-IQ automate this process so you’re not stuck doing manual comparisons.

5. Minimizing void space

Why it’s a problem: Extra space in a box equals extra cost. ANd with dimensional weight, it doesn’t take much air to drive up the price.

How to avoid it: Optimize void fill and packaging selection. For multi-item orders, use cartonization software to maximize your use of space and reduce dimensional charges.

Explore smarter palletization strategies.

Account for dimensional weight with Cube-IQ

Most businesses calculate dimensional weight after the fact—once the items are packed, taped up, and ready to ship. By then, it’s too late to optimize. Manual estimates or static calculators miss cost-saving opportunities because they react instead of plan.

Cube-IQ flips the script. It accounts for dimensional weight during load planning before a single box is packed. That way, you can make strategic decisions from the start. It updates in real time as your configurations change and supports mixed units for international teams juggling inches and centimeters, pounds and kilos.

The result? Smarter packing and real savings. Cube-IQ simulates different packing options to help you choose the most efficient one, whether you’re trying to minimize box size, avoid airspace, or reduce freight charges. It’s proactive, precise, and built to cut costs before they stack up.

Common mistakes and how to avoid them

Even small missteps in how you pack and measure can lead to big shipping costs. From choosing the wrong box to forgetting the weight of the bubble wrap, you should make every effort to avoid these five common dimensional weight mistakes.

1. Incorrect box size

Using a box that’s too big for your product may seem harmless, but oversized boxes inflate dimensional weight and increase shipping costs.

Avoid it: Choose boxes that closely match the size of your product. Cut down on excess space and consider custom-sized packaging if your items are consistent in shape and size.

2. Neglecting packaging weight

Packing materials add more weight than you think. Bubble wrap, foam inserts, air pillows, tape—it all adds up. And if you’re not accounting for it, you could end up drastically underestimating shipping costs or undercharging your customers.

Avoid it: Weigh the entire package after it’s packed, not just the product inside. Keep a running tally of common packaging material and their weights to improve future estimates and margin accuracy.

3. Inaccurate measurements

When it comes to DIM weight, an inch can make a big difference. Rounding down or skipping the re-measure after packing can lead to billing discrepancies, unexpected charges, or even reclassification from many carriers.

Avoid it: Measure from the longest points on each side of the box and always round up to the nearest whole inch. Use the same measuring tools across your operation for consistency and accuracy.

4. Dimensional weight vs. actual weight

It’s easy to focus on the number the scale gives you, but that’s only half the equation. Many shipping teams overlook dimensional weight entirely and end up surprised by higher charges when the carrier defaults to the larger number.

Avoid it: Calculate both the actual weight and the dimensional weight every time. Bill based on whichever is higher, or use a solution like Cube-IQ to automate this step and ensure your rates are accurate from the start.

5. Minimizing void space

Void space is the silent cost driver in shipping. The more air in your box, the more you’re charged. And it doesn’t take much extra room to tip the scales against you.

Avoid it: Use void fill to stabilize items, but don’t overdo it. Select packaging that fits the contents snugly, and for multi-item orders, consider mixed palletization strategies to make the most of your space. Explore smarter palletization strategies.

Smarter Packing Starts Here

Dimensional weight charges may seem like just another shipping fee, but when ignored, they quietly inflate your costs. The good news? They’re also one of the easiest areas to control if you plan ahead.

Cube-IQ helps you stop shipping air and start shipping smarter. With real-time optimization, flexible unit support, and automated comparisons, your team can right-size packaging, minimize void space, and keep dimensional charges in check.

Ready to turn your packing peanuts into profit? Get started with Cube-IQ today.