Organize Your Shipping Systems With Palletization Software

Palletization software is a vital part of supply chain operations and is designed to help with the process of placing items to be shipped onto pallets. The software automates what has historically been a manual and time-consuming task, ensuring that goods are arranged efficiently and securely on pallets to maximize space, reduce the risk of damage, and improve overall handling.

What is palletization

Palletization is the process of stacking goods or materials onto a pallet, a flat structure designed to support and stabilize them during storage and transportation. The main purpose of pallet building software is to organize the handling, storage, and movement of goods, making them easier to transport by forklifts, trucks, and other machinery. When pallets were originally introduced, the impact on material handling was dramatic.

Benefits of palletization

Faster delivery

Using pallets as a base for goods allows them to be loaded and unloaded far more quickly and efficiently, saving hours of human resources, reducing labor costs, and enabling a faster turnaround and transportation of products.

More efficient handling

Operators can insert and remove pallets more effectively, as handling equipment can stack products, reducing the number of movements required.

Lower labor costs

Labor requirements are reduced dramatically with palletization. Moving fully loaded pallets allows warehouse workers to move a greater volume of goods during each shift.

Protection of perishable goods

Palletization is particularly important for perishable goods that must be kept refrigerated. Using pallets allows these goods to be moved more quickly across unrefrigerated areas, and they can be loaded and unloaded more quickly.

Lower risk of damaged goods and freight loss

Proper palletization reduces damage to goods, protecting items and ensuring that products remain in perfect condition until the pallet is unloaded and ready for the next part of the supply chain. Items secured on pallets are bound together with plastic wrap, strapping, or both, so the chance of items falling off are low.

Warehouse staff safety

When items are palletized correctly, the pallet is stable, reducing the chance of injury to workers.

Warehouse storage optimization

Material handling is more efficient, enabling better optimization of warehouse storage, since one key factor in optimizing transportation is stackability.

Better inventory control

Palletizing loads enables better inventory control, as it is easier to monitor each SKU. Logistics managers can gauge a product’s stock level at a glance since they will know the number of products stored on each pallet.

Versatility

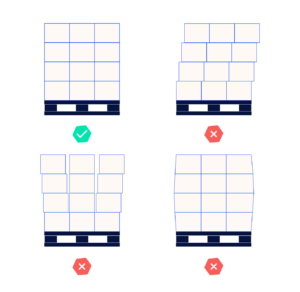

Usually, goods loaded onto pallets are stacked on top of one another in columns, resting directly on the item below. However, load strength and stability considerably increase when pallets are loaded in an interlocking pattern. Achieving the best loading pattern is not easy. Additionally, some goods are not suitable for palletization. These include long and thin items or irregularly shaped items that will not stack easily.

Choosing the best way to palletize

You can choose from a variety of palletization methods, as long as you keep stability in mind. The following tips will improve your palletization process:

- Use cartons or boxes: Opt for regular-shaped cartons or boxes to ensure goods can be neatly stacked, resulting in more even loading.

- Fill to max capacity: Pack the boxes as full as possible within weight and size limits.

- Ensure even stacking: Avoid uneven stacking or bulging loads to maintain stability, and be sure to distribute items on the pallet evenly by weight.

- Create a compact structure: Aim for a compact and uniform load structure for enhanced stability, without any items extending past the pallet base.

- Wrap the load with transparent film: Secure the load by wrapping it in transparent film to protect the goods and keep them together.

- Use strapping for additional security: Consider using strapping to further secure the load and bind the goods together.

Consider pallet characteristics

Pallets are available in several standard sizes, helping optimize supply chain operations. A standard pallet is 40 x 48 x 5 inches, and most shipping companies base their freight charges on pallet volume. Using pallets can add 20% – 30% volume to a shipment, so proper optimization is essential to ensure the pallets achieve maximum volume. Most companies use standard-sized boxes that are easier to stack without wasting space, but this isn’t possible for every order.

Pallets can be made from different materials, depending on the goods to be shipped. These include pallets made from wood, metal, or plastic. Pallets can also be selected according to the storage systems available in the warehouse, the handling equipment that can be manual or automatic, and facilities available at supplier locations.

Using blackbox logistics pallet loading software

MagicLogic BlackBox software includes a separate optimization engine developed specifically for palletization, including complex mixed-case pallet stacking. Our palletizing software can build layers and semi-layers. It can also automatically switch to free stacking when required. The main aim of our palletization engine is to achieve excellent pallet stability, maximum fill quality, and maximum load stability. It supports manual pack stations and robotics.

These days, more companies are choosing to automate or semi-automate their logistics operations, and BlackBox can provide packing sequences suitable for robotics. Robotics is especially useful for packaging pharmaceutical goods and the food industry, ensuring goods remain clean and hygienic during palletization.

Our BlackBox palletization software includes configurable parameters for different end-of-arm tools and approach points, allowing users to achieve true mixed case robotized palletization. Our R&D team spent considerable time solving this difficult problem effectively and is rightly proud of this achievement.

Easy to integrate with your WMS/TMS

Nous avons conçu notre BlackBox de manière à ce qu'elle puisse être configurée pour fonctionner avec n'importe quel système générant des données selon un schéma standard, en utilisant des API puissantes qui garantissent aux intégrateurs de systèmes d'être opérationnels en l'espace de quelques jours.

Custom solutions available

Over half of our business focuses on providing custom solutions to meet customers’ specific requirements. Many of our customers need to ship products that must be packed in a certain way to ensure they arrive in perfect condition and are accepted by the end-user. We specialize in finding solutions for tricky problems using our decades of experience and knowledge gained within the supply chain industry. For more information you can reach out to our customer success team.