When you’re in logistics, your world never stops moving—and neither should your freight. Whether you’re managing intermodal shipments, ocean freight, or last-mile deliveries, inefficiencies in container planning and tracking can cost you time, money, and customer satisfaction. Shipping container software will help you eliminate inefficiencies and keep your operations running smoothly.

Understanding shipping container software

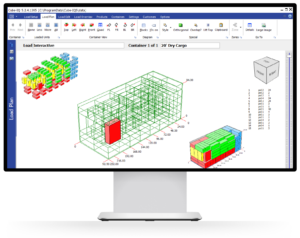

Shipping container software optimizes how your cargo is packed and loaded, streamlining the logistics workflow. It ensures that every container is filled efficiently, minimizing wasted space while maximizing stability. This is accomplished, in part, through integrations with warehouse management systems (WMS), transportation management systems (TMS), and enterprise resource planning (ERP) platforms to streamline the logistics process from end-to-end. Shipping container softer software can help your business cut costs, save space, and operate more efficiently.

Key benefits of shipping container software

Optimizing how your shipments are packed and processed can make a huge impact. Advanced load planning and containerization will help you eliminate inefficiencies, maximize throughput, save on shipping and transportation costs, and even improve the carbon footprint of your supply chain. Here’s a bit more information:

-

- Lower shipping costs: Efficient load planning means fewer containers, better use of space, and reduced dimensional weight charges—all of which lead to significant cost savings when it comes to transportation and shipping.

-

- Faster load planning and execution: Automated container planning eliminates manual trial and error, ensuring your shipments are optimized in seconds instead of hours. To bring this to a personal level, imagine the time and hassle you’d save if you could use load planning software next time you pack up your car for a road trip!

-

- Improved throughput and reduced bottlenecks: Smart cartonization, palletization, and container optimization allows your warehouses and distribution centers to move freight faster, reducing processing delays.

-

- Better use of space: Advanced algorithms in shipping container software ensure that every container is packed to maximize available space, reducing wasted air space and unnecessary shipments.

-

- Enhanced load stability and compliance: Poorly loaded containers can lead to damaged goods and rejected shipments. An advanced software solution will optimize weight distribution, stacking rules, and compliance with carrier requirements, preventing costly disruptions.

-

- Scalability for high-volume operations: Whether you’re shipping a few pallets or managing millions of shipments, shipping container software will automate the process at scale, ensuring efficient load planning for high-volume shippers.

-

- Lower environmental impact: The efficient use of space within a container ensures that you’ll use the least number of containers possible and that less void filler is necessary, both of which lower the carbon footprint of shipping your goods.

Using container software will eliminate inefficiencies and keep your freight moving as smoothly as your dog sliding into the warm spot on the couch the second you stand up.

How shipping container software works

Shipping container software streamlines load planning, ensuring that every container, pallet, and carton is packed efficiently. Here’s how the process works:

Step 1: Input your shipment data

Thanks to those integrations, shipping container software ingests your order details, including dimensions, weight, stacking constraints, and destination requirements. This will ensure that each shipment is optimized based on real-world parameters rather than guesswork.

Step 2: Let the algorithms calculate the best fit

Advanced loading algorithms determine the best way to pack your items into cartons, pallets, and containers. The system accounts for weight distribution, stability, and carrier-specific rules to prevent costly misloads or rejected shipments.

Step 3: Finalize and execute your load plan

The system generates a detailed packing plan that includes container layouts and load sequencing data to guide warehouse teams or robotics systems. This ensures faster fulfillment, optimized freight costs, and fewer delays in transit.

By automating and optimizing containerization, shipping container software eliminates inefficiencies before shipments even hit the road. The result? Fewer errors, less manual labor, and a supply chain that runs like a well-oiled machine.

The role of shipping container software in logistics optimization

Shipping container software will help your business maximize efficiency, reduce costs, and improve the overall flow of your goods through the supply chain. By automating load planning and optimizing your use of space, you’ll eliminate inefficiencies before your shipments leave the warehouse.

Plan smarter loads

Instead of relying on manual calculations, advanced algorithms determine the most efficient way to load freight into containers, pallets, or cartons, reducing wasted space and unnecessary shipments.

Fulfill orders faster

Automated load planning means your warehouse teams will spend less time figuring out how to pack shipments and more time getting orders out the door. This speeds up fulfillment and prevents costly delays.

Integrate seamlessly with your supply chain

Shipping container software that connects directly with your WMS, TMS, and ERP platforms allows your loading plans to be instantly available, and that reduces errors and keeps your logistics operations running smoothly.

Reduce your transportation costs

Optimized shipments means fewer containers, better use of space, and lower transportation costs. Your business can move more freight with fewer resources, making shipping more cost-effective.

Eliminating inefficiencies at the packing and planning stage will ensure that your freight moves through your supply chain without unnecessary slowdowns or costly mistakes.

Why shipping container software matters

Shipping container software, also known as load planning software, isn’t just about packing cargo efficiently—it’s about cutting costs, reducing waste, and improving your supply chain performance. By optimizing load planning and reducing inefficiencies, it delivers measurable benefits that impact both business operations and sustainability.

-

- Lower transportation costs: Every inch of wasted space in a container is money lost. Optimizing cartonization, palletization, and container loading reduces the number of shipments needed, leading to lower freight costs and fewer unnecessary surcharges. Learn more about efficient load planning with Cube-IQ.

-

- Environmental benefits: Reducing empty space means fewer shipments on the road, which lowers fuel consumption and emissions. Optimized loads contribute to a greener supply chain by cutting down on packaging waste and unnecessary transportation.

-

- Improved customer satisfaction: Faster, more efficient shipping leads to on-time deliveries, fewer damaged goods, and a more reliable experience for customers. Businesses that optimize their shipping processes can better meet delivery expectations and improve customer retention.

Eliminating inefficiencies before shipments leave the dock helps every load to be cost efficient, sustainable, and better at meeting customer expectations.

Innovations in shipping container software

The world is evolving rapidly, and that includes shipping and load planning software. Breakthrough technologies are redefining efficiency, flexibility, and decision-making. Take EasyPost Luma, for example—EasyPost’s new, unrivaled, shipping AI designed to revolutionize shipping intelligence.

From AI-powered load optimization to real-time cloud-based solutions, the next wave of innovations will reshape how you plan, pack, and ship containers. These advancements will shape the future of container optimization:

-

- AI in load optimization: Artificial intelligence will transform load planning by improving optimization algorithms based on real-world shipping data. Soon, AI-driven load planning tools will be able to analyze vast amounts of shipping data to predict the most efficient packing strategies, adapt in real time to disruptions, and self-optimize over time based on past performance.

-

- Cloud-based solutions for real-time access to load plans: As supply chains become more dynamic, real-time processing is essential. Modern shipping container software is moving to the cloud, allowing logistics teams to access optimized load plans from anywhere. This enables seamless collaboration between warehouses, carriers, and supply chain partners, ensuring that everyone works with the most up-to-date information.

-

- Autonomous load planning and execution: Yep, robots. Warehouse automation is evolving, and load planning software will need to integrate seamlessly with robotic palletizers, autonomous forklifts, and smart conveyor systems. Software that not only plans the optimal load but also directly communicates with robotics to execute it will significantly improve efficiency. (Psst, it’s already happening with Cube-IQ.)

-

- Digital twins for load planning: Have you heard of this one? A digital twin is a virtual replica of a physical system. Future load planning software may create real-time digital twins of cargo, warehouses, and transport fleets to simulate load scenarios, predict inefficiencies, and continuously refine packing strategies.

-

- Deeper integration with supply chain visibility tools: Load planning tools will need to become more interconnected with supply chain visibility platforms offering predictive analytics, automated adjustments, and greater interoperability with multi-carrier shipping networks. The data is there—we just need to make the right connections to use it better.

-

- Self-correcting load plans based on IoT and sensor data: Future load planning solutions could integrate with IoT sensors inside containers and trucks to detect shifting loads, temperature fluctuations, or cargo damage in transit—and then adjust future load plans accordingly.

Who knew the future of shipping container software could be so exciting?

Implementing shipping container software with Magic Logic

As your supply chain grows more complex, MagicLogic’s solutions will ensure that your business stays ahead with seamless system optimization, highly customizable load planning, and lightning-fast load plans. Whether you’re handling cartons, pallets, or containers, our advanced algorithms deliver precise, efficient load plans that reduce freight costs and maximize throughput.

With customizable tools designed to fit diverse shipping needs, MagicLogic will help you create load plans that align with your specific requirements. Contact us to see how MagicLogic can transform your container planning strategy, or download the software today and get started!