Load Planning Software: Streamline Your Logistics With Ease

We’ve all been there, standing in the airplane aisle, watching someone wrestle their oversized carry-on into the overhead bin. First it goes upright, then sideways, then they push and slam until a flight attendant steps in, gives the bag a twist, and—like magic—it slides right into place.

A flight attendant’s know-how illustrates the difference between guessing and knowing. In logistics, that same awkward overhead-bin struggle happens on a much bigger scale when planners try to figure out how pallets, boxes, and containers fit into trucks or shipping containers. Do it by hand, and it’s a slow, frustrating game of trial and error. Use load planning software, and suddenly it’s as smooth as a flight attendant breezing down the aisle.

Smart load planning is the backbone of efficient logistics. It saves money, speeds up workflows, and keeps shipments protected. Up next, we’ll unpack how load planning software works, why it beats manual planning every time, and how it can turn your logistics operation into a first-class experience.

Understanding load planning software

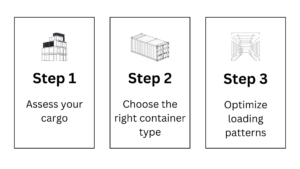

Load planning software is like your personal crew of expert flight attendants for the shipping world. Instead of eyeballing boxes and hoping they fit, the software calculates the best possible way to arrange cargo inside a truck, trailer, or container. It takes into account size, weight, stacking rules, and compliance requirements, then delivers an efficient, accurate, and safe plan.

Manual planning, on the other hand, is a lot like passengers cramming bags into bins without a clue—it might work eventually, but not without wasted time, wasted space, and possibly some damage along the way. Software brings order to the chaos, instantly showing you how everything should fit so your cargo is loaded right the first time.

In short: where manual planning leaves you stuck in the aisle, blocking traffic, load planning software gets everyone seated and ready for takeoff.

Features of load planning software

Load planning software comes with a toolkit designed to make logistics smoother, smarter, and faster. These standout features take cargo loading from guesswork to precision:

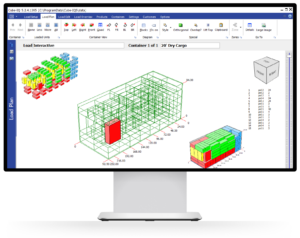

3D visualization

When planners can see a load before it’s packed, everything changes. 3D visualization turns numbers and spreadsheets into a clear picture of how freight fits together inside a container or truck. Instead of hoping dimensions line up, teams can rotate, zoom, and explore loads in a virtual space. The result is fewer surprises, fewer adjustments during loading, and more confidence that every shipment is arranged for maximum efficiency and safety.

Automated load calculation

Manual planning relies on trial and error, which costs valuable time. Automated calculation eliminates the guesswork by instantly generating optimized load plans. The software weighs dimensions, stacking rules, and safety requirements in seconds, producing results that might take hours to figure out by hand.

User interface

Even the most powerful software fails if users struggle to navigate it. A well-designed interface keeps the planning process straightforward—drag, drop, adjust, and review without wading through clunky menus. Plus, the easier it is to use, the more likely teams are to adopt it, which ensures that the investment pays off in actual day-to-day efficiency.

Compliance tools

Regulatory and safety requirements are a constant in logistics, and missing them can lead to costly delays or fines. Compliance tools act as guardrails, ensuring that every load meets the rules. These built-in checks protect companies from errors that can slip past manual planning, reducing risk, saving money, and ensuring shipments reach their destinations without unnecessary holdups.

Integration capabilities

Integration capabilities connect the software with WMS, ERP, and TMS platforms so information flows seamlessly across the supply chain. Order data comes in automatically, optimized load plans flow back out, and everything stays in sync without manual data entry. This level of integration not only saves time but also improves accuracy, since everyone in the operation works from the same set of information.

Benefits of load planning software

Load planning software gives logistics teams an edge. The benefits that make the biggest impact are listed below:

Cost efficiency

Empty space in a truck is like an empty seat on a flight—revenue lost and opportunity wasted. Load planning software reduces that waste by squeezing maximum value from every run. Better use of space means fewer trips, less fuel, and more money saved. For companies operating at scale, those savings add up to serious bottom-line impact.

Accuracy

Guesswork in logistics leads to the same outcome as a passenger trying to shove a suitcase the wrong way into the overhead: frustration, wasted time, space inefficiency, and potential damage. With software, loads follow precise calculations that take size, weight, fragility, and stacking rules into account. That accuracy protects shipments while preventing the ripple effects of damaged goods, rejected loads, or safety violations.

Time savings

When cargo planning happens by hand, it slows everything down like a boarding process where every traveler argues over whether their bag will fit. Automation changes the pace. Load planning software builds plans in minutes, not hours, allowing trucks to hit the road faster and shipments to arrive sooner. Shippers save time in the warehouse and gain reliability in transit.

Scalability

Airlines don’t change their process when they move from small commuter planes to jumbo jets, they scale it. Load planning software works the same way. Whether a business needs to plan a handful of pallets or hundreds of containers across global routes, the system adapts without extra strain. As operations expand, the software keeps pace, ensuring efficiency stays high even under heavier demand.

Types of load planning software

Load planning software can be grouped in two ways: by functionality (whether it runs on its own or ties into other systems) and by deployment (whether it’s installed locally or hosted in the cloud). Understanding where you fall on both axes helps you zero in on the right solution for your team.

Functionality: standalone vs. integrated

Standalone

Standalone software works independently. It doesn’t rely on a warehouse management system (WMS), enterprise resource planning system (ERP), or transportation management system (TMS) to run. This setup gives planners full control of their load planning process without needing data from larger platforms. It’s often used by companies that want to test out optimization tools or by smaller teams that prefer a lightweight setup.

Integrated

Integrated software connects directly into existing systems so data flows automatically. Instead of exporting order details, running them through a separate program, and re-importing results, the optimization happens within the tools you already use. This approach is especially valuable for large-scale operations where speed and automation matter, since it eliminates manual steps and reduces the risk of errors.

Deployment: on-premises vs. cloud-based

On-premises

On-premises (or on-prem) software is installed on a company’s own servers or desktops. It offers greater control and the ability to customize the solution to unique operational needs. Many businesses prefer this approach when they have strict security requirements or want to manage everything internally. While it requires more IT resources, it can provide unmatched flexibility in tailoring the software.

Cloud-based

Cloud-based software lives online, accessible from anywhere with an internet connection. This approach removes the burden of local installation and ongoing maintenance, since updates and new features are rolled out automatically. Cloud platforms scale easily as business grows, and planners gain the flexibility to work from any location.

Choosing the right load planning software

Picking load planning software is a lot like choosing an airline. You want the right balance of reliability, comfort, and cost. And once you’ve had a bad experience, you won’t make the same mistake twice. The stakes are high, so it pays to look closely at a few key factors:

Scalability

A load planning solution should serve your business today and grow with it tomorrow. Many companies start with a single facility or a handful of trucks, but as orders increase, new locations open, and shipping networks expand, complexity skyrockets. Software that scales gracefully prevents growing pains by handling larger volumes, more diverse cargo, and multi-location coordination without slowing down.

The best systems don’t just stretch to accommodate growth, they adapt. Whether you’re adding new product lines, shipping internationally, or managing seasonal surges, scalable load planning software keeps performance consistent. That flexibility ensures you can say yes to new opportunities without worrying about whether your logistics tools can keep up.

Ease of use

Sophisticated software doesn’t help if nobody wants to use it. Load planning already comes with enough moving parts; the interface should simplify, not complicate. A clear, intuitive design gives planners the confidence to move quickly, test scenarios, and make adjustments without digging through menus or relying on IT support.

Ease of use plays directly into speed of adoption. When the system feels approachable, teams are more likely to embrace it as part of their daily routine. That leads to fewer errors, less training time, and smoother collaboration across departments. The right software feels less like “another system to learn” and more like a natural extension of the way planners already work.

Integration

Disconnected systems create bottlenecks, slow down workflows, and increase the risk of mistakes. Load planning works best when it doesn’t live in isolation but connects with the systems you already rely on: your WMS, ERP, or TMS. With integration in place, order details flow in automatically, optimized load plans flow out, and the entire process runs without the need for double entry or manual transfers.

Strong integration doesn’t just save time, it creates consistency. Planners, warehouse teams, and transportation managers all work from the same data, which means fewer errors, faster turnaround, and smoother communication between departments. In many cases, integration is what turns load planning software from a helpful tool into a core part of daily operations.

Trial runs

Just as you might try a new airline before booking a long-haul trip, testing load planning software before committing gives you real-world proof of how it performs. A trial period helps you see whether it fits your workflows and delivers the efficiency gains you expect.

The best choice isn’t always the most feature-packed; it’s the one that matches your operation, adapts to your growth, and makes life easier for your team now and in the future.

Future of load planning software

Load planning software has already transformed how companies manage cargo, but the tools of today are only the beginning. The future points toward even smarter, faster, and more connected systems.

Artificial intelligence and machine learning

AI-driven systems are learning to recognize patterns in shipping data and recommend the most efficient strategies. Instead of simply generating a load plan, future software will anticipate demand, spot inefficiencies, and fine-tune configurations automatically. Machine learning will also improve with use, because the more data the system processes, the sharper and more accurate it becomes.

Cloud-based collaboration

As logistics networks stretch across borders, cloud-based platforms will continue to gain traction. Teams in different locations will be able to view, adjust, and share load plans in real time. Think of it as upgrading from a paper ticket to a digital one stored in your phone wallet—accessible anywhere, instantly updated, and nearly impossible to lose.

Predictive analytics

Tomorrow’s software won’t just tell you how to load cargo, it will forecast the best way to prepare for what’s coming. By analyzing historical data and current trends, predictive analytics can help companies anticipate peak periods, avoid bottlenecks, and adjust resources before problems appear.

The future of load planning looks less like a manual process and more like an intelligent co-pilot. One that not only charts the course but also keeps adjusting to ensure the smoothest ride possible.

The direction of the industry is clear: smarter, faster, and more connected systems will define the next era of logistics. That’s why choosing the right partner matters. MagicLogic has been building toward this future for decades, delivering tools that already put many of these capabilities into practice.

Why MagicLogic stands out

Load planning software isn’t one-size-fits-all, and neither is MagicLogic. Instead, MagicLogic offers solutions built for different needs, from desktop planning to cloud-based collaboration to fully embedded integrations. Whether you’re planning cartons, pallets, trucks, containers, or even airplanes, MagicLogic adapts to the task. No matter how you deploy it, the goal is the same: smarter loads, smoother operations, and logistics that feel more like a first-class experience than a middle-seat scramble.

Cube-IQ

Our flagship load planning solution, Cube-IQ, has been trusted by logistics teams worldwide for decades. Installed on-premises, it gives planners full control over their load plans with powerful optimization tools, customizable business rules, and 3D visualization. Cube-IQ is perfect for companies that want the reliability of a proven system hosted in-house.

Cube-IQ Web

For teams that need flexibility and easy access from anywhere, Cube-IQ Web brings the power of Cube-IQ to the cloud. With no software to install, updates roll out automatically and planners can collaborate across locations in real time. It’s a modern solution that scales effortlessly as your business grows.

BlackBox

Sometimes the best load planning software is the kind you don’t even notice. BlackBox embeds MagicLogic’s optimization engine directly into your WMS, ERP, or TMS. It runs in the background, turning order data into optimized load plans without any extra steps for your team. For companies that want automation at scale, BlackBox is the ultimate hands-off solution.

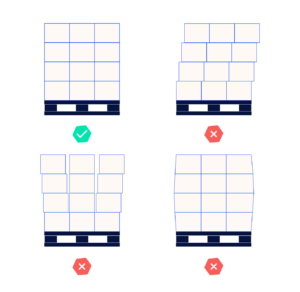

Stack-IQ

Stack-IQ specializes in pallet planning, stacking, and bay truck loading. It’s designed for operations that handle heavy or awkwardly shaped products, where stability and efficiency matter most. The software builds secure pallets that protect cargo, then optimizes how those pallets fit into a truck bay. The result is dependable, space-saving loads that move safely from warehouse to delivery.

MagicLogic takes the guesswork out of load planning so your logistics operation runs with precision. From standalone desktop software to cloud-based platforms to fully integrated engines, we deliver solutions that fit your operation today and grow with you tomorrow.

Ready to see it in action? Try Cube-IQ for free and experience smarter load planning for yourself.