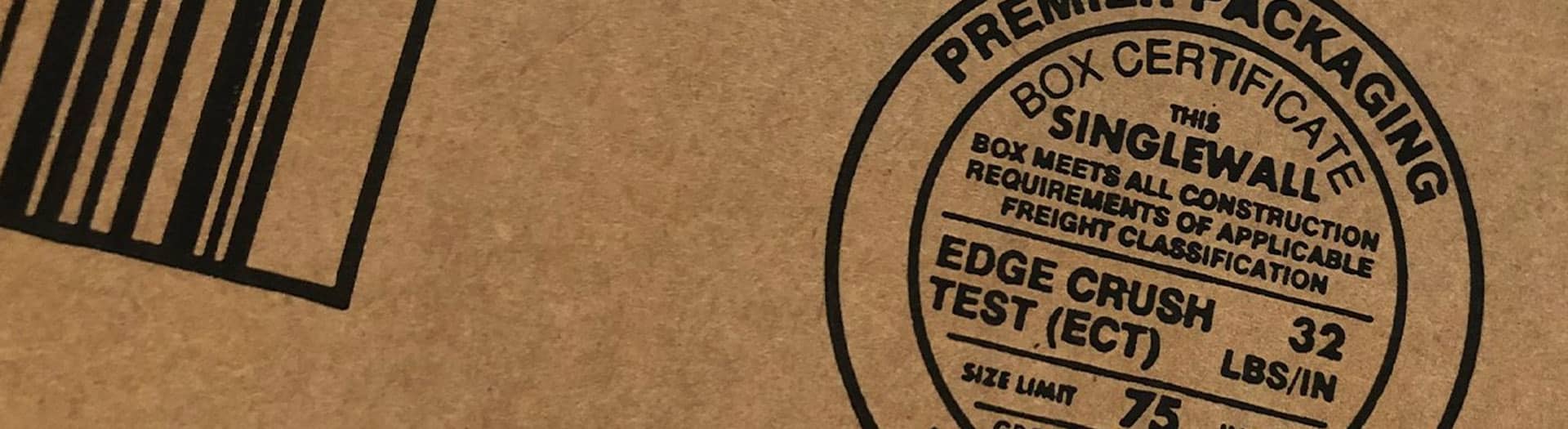

Customers take it for granted that their items will arrive properly packaged and, most importantly, in the right box. However, choosing the correct box for every shipment relies on understanding the Box Certificate, or Box Manufacturer’s Certificate, found on the base of most cardboard boxes.

The certificate contains a wealth of information about the specifications of the box, relating to its size, construction, and weight limits. A Box Certificate will tell you if your chosen carton is adequate for shipping a specific order and can provide enough protection for the contents. So, what can you expect to learn from this certificate?

Box construction

The Box Certificate tells you how the box is constructed, for example, if it has a single, double or triple wall of corrugated board.

If you choose a single wall carton, it has a fluted medium inserted between two layers of liner board. In comparison, a carton with a double wall box has two fluted mediums between three liner boards. A triple walled carton has three fluted mediums held between four layers of liner board.

Box weight

The basis weight of the box is given as pounds per thousand square feet and relates directly to the strength of the box. A box with a higher basis weight has greater tensile strength.

Box strength

The box strength weighting relates to burst strength, which is the tensile and tearing strength and is given as pounds per square inch. The burst strength refers to how well the material can contain its contents when under stress. Strength weighting also measures the edge crush strength, which is the compressive strength is measured from top to bottom.

Boxes that need a greater burst strength require a greater basis weight. Boxes that need a better edge crush value will achieve this through the vertically oriented flutes of the corrugated cardboard, allowing manufacturers to lower the basis weight. As a rule of thumb, heavier or denser items need packaging with a greater burst strength, whereas items that need more protection against becoming crushed need a greater edge crush value.

Carton size

The size of the carton indicates the maximum outside dimensions of the completed box when you add together its length, width, and depth. Generally, as the box size increases, its contribution to overall strength decreases.

Gross weight

The gross weight listed on a carton indicates the maximum weight the carton can contain, but this doesn’t necessarily mean contents loaded up to the gross weight will arrive in perfect condition. This depends on several factors that include the product characteristics and the way it is transported.

Usually, the weight limits are more applicable for items that are palletized and which are transported in freight shipments as opposed to those shipped via smaller carriers.

Do I need a Box Certificate?

Determining whether you need a Box Certificate depends on the type of products you are shipping and the shipping methods you use. Consider the following key factors:

Product fragility: If you’re shipping fragile or expensive items, a certified box ensures that the packaging can handle the required protection during transit.

Shipment weight: Heavy items require boxes with higher weight capacity ratings, which are indicated on the Box Maker’s Certificate.

Shipping regulations: Certain industries, such as pharmaceuticals or food products, require certified boxes to meet regulatory standards.

Shipping volume: Businesses handling large-scale shipping operations benefit from using certified boxes to maintain consistency in packaging quality and reduce the risk of damage.

Environmental impact: If sustainability is a priority, using certified boxes ensures that you’re selecting packaging materials that comply with environmental standards.

How to read a Box Certificate

Understanding the information on a Box Maker’s Certificate can be essential for selecting the right packaging. This guide will help you interpret the main sections of the certificate:

Box type: Identifies the type of box, such as single-wall or double-wall, indicating the strength of the box.

ECT/Burst rating: Specifies the compression or burst resistance of the box, helping you select boxes that meet your specific needs.

Manufacturer details: Includes information about the manufacturer to confirm the box’s source and quality.

Box grade: Provides a numeric or letter grade that reflects the quality of the corrugated material.

Selecting the optimal carton

When it comes to excellent cartonization, you can rely on MagicLogic’s BlackBox. The main features of this clever, easy-to-integrate software include cartonization and mixed palletization. The best boxes are selected from your stock order after order, providing near real-time responses that are ideal for use during checkout in e-fulfilment. It supports complex mixed pallet stacking, including robotics, ensuring delicate items are never crushed.

Contact us to discover how BlackBox will streamline your cartonization and palletization processes.